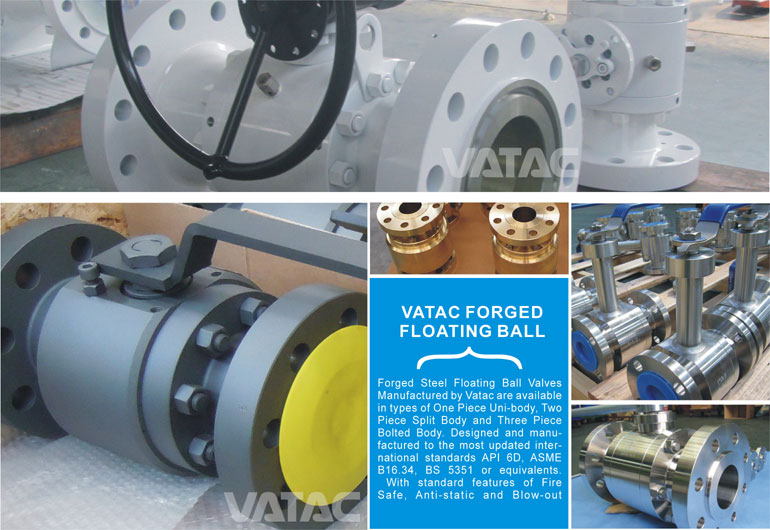

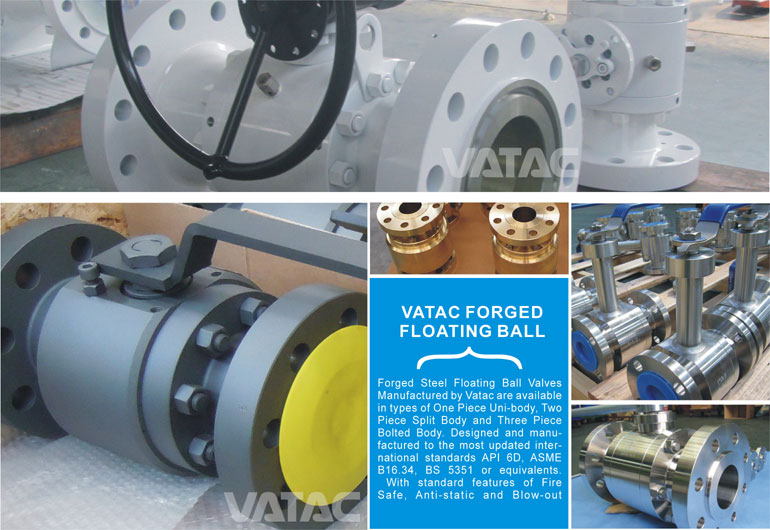

Product Description

Model NO.: Q41F Connection Form: Flange Nominal Pressure: ANSI CLASS 150-900 Structure:

Floating Ball Valve Application: Industrial Usage, Water Industrial Usage, Household Usage Design & Manufacture: API 6D, Asme B16.34 & BS5351 Face to Face: Asme B16.10 Inspect & Test: API 598 Certificate 2: ISO 9001: 2008 Certificate 4: API 6D Specification: API, ANSI, ASME, DIN, JIS etc. HS Code: 84818010 Material: Stainless Steel Driving Mode: Manual Channel: Straight Through Type Type: Floating

Ball Valve Characteristic: 1/2" to 6" Nb Pre-Temp. Rating: Asme B16.34 Ends Connection: RF, NPT, Bw, Sw Certificate 1: Dnv CE 0575 Certificate 3: API 600 Trademark: VATAC Origin: China

API/DIN Forged Steel Ball Valve (Q41F) Features:

Manufacture in Forged and Casting Materials: WCB, A105, SS304, SS316 & Duplex etc. Other Materials available upon Request

Various Trim and Seat (Resilient and Metal) Materials available To Suit Different Service Condtions

Pressure Rating: CL150, CL300, CL600, CL900, CL1500, CL2500

Flanged (RB, F. P) Ends to ANSI B16.5 Face to Face Dimension to ANSI B16.10

Pre-temp. Rating to ASME B16.34

Wall Thickness to ASME B16.34

Size Ranges: 1/2 ~8"

Optional Lockable Handle Lever

Blow-Out Proof Stem

Fire Safe Design to API 6FA

Inspect & Test: API 6D / API598

Valve Marking: MSS- SP-25

To MR-01-75 On Request

Pictures

FOUNDRY - CASTING * FORGING

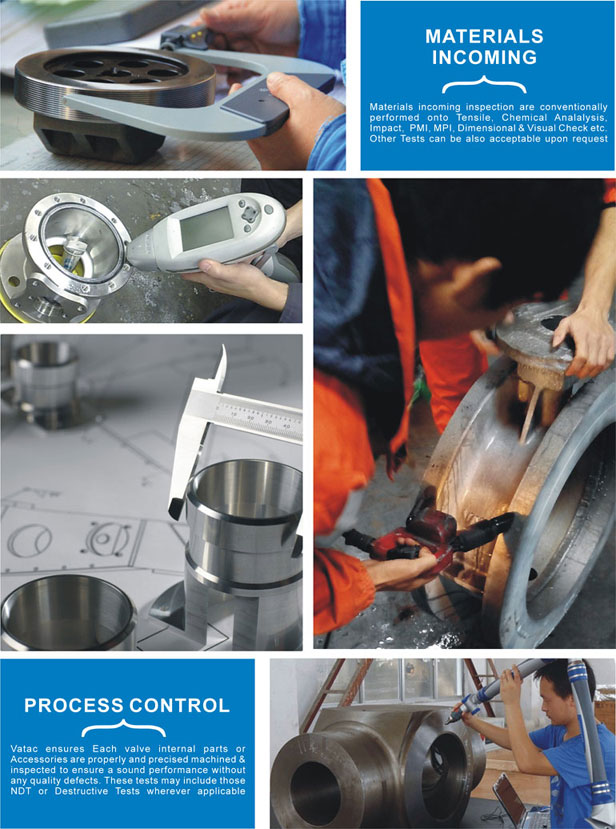

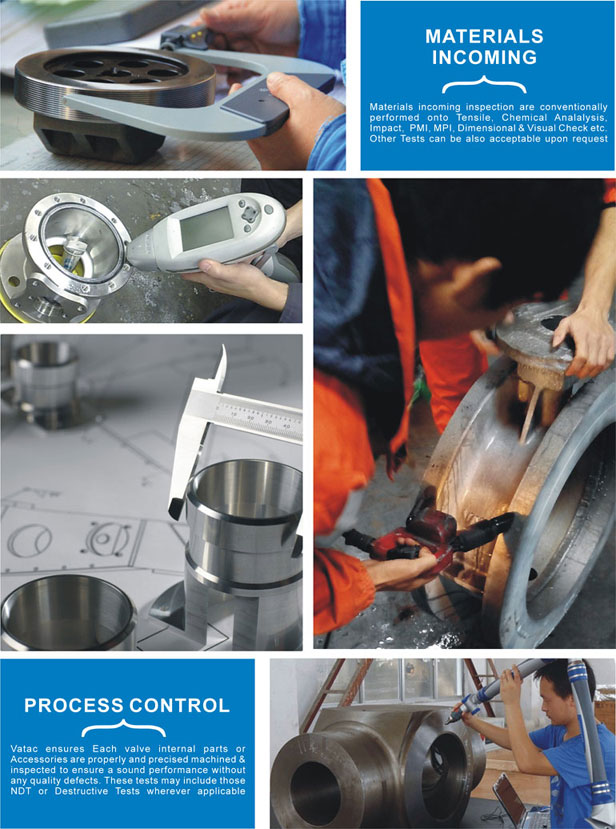

MACHINING AND IN-PROCESS CONTROL

| Construction is as follows: |

|

|

| - Full Port or Reduce Port |

| - One Piece or Split Body |

| - Bolted Bonnet with spiral-would gasket |

| - Fire Safe Design |

| - Anti-static Design & Blow-out proof stem |

| - Socket Weld Ends to ASME B16.11 |

| - Butt Weld Ends to ASME B16.25 |

| - Screwed Ends to ANSI/ASME B1.20.1 |

| - Flanged Ends to ASME B16.5 |

2. Main Part & Materials

| Part Names | Part Materials |

| Body | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Bonnet | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Ball | A105+ENP | SS304 | F22 | SS304 | SS316 | SS304L | SS316L |

| Stem | A105 | F304 | F6a | F304 | F316 | F304L | F316L |

| Seat/Seat Ring | PTFE/RPTFE/NYLON/DEVLON/PEEK or METAL |

| Packing | Graphite/PTFE |

| Gasket | SS304+Graphite/SS316+Graphite |

| Bolts/Nuts | B7/2H | L7/4 | B16/4 | B8/8 | B8M/8M | B8/8 | B8M/8M |

| Suitable Medium | W.O.G etc. | HNO3, CH3OOH etc. |

| Suitable Temperature | -29~425 °C | -46~340 °C | -46~340 °C | -196~427 °C | -196~427 °C | -196~427 °C | -196~427 °C |

Contact us if you need more details on Forged Steel Ball Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about API Forged Steel Ball Valve、DIN Forged Steel Ball Valve. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Ball Valve > DBB&Trunnion Ball Valve