| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 25 Days |

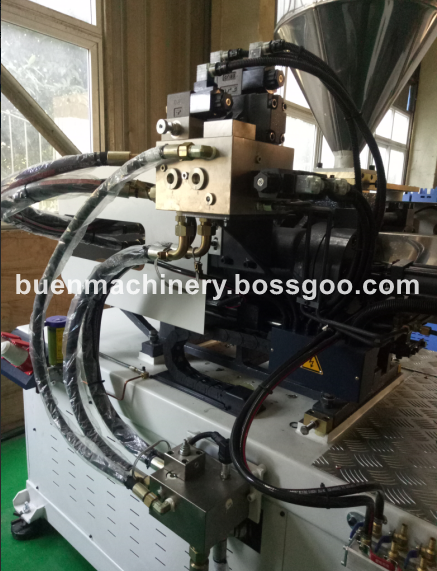

Model No.: BN-380S

Here is our model BN-380S injection molding machine which is suitable for different types of plastic products such as dust bins,storage boxes ...

We hope to offer you best solution for your products.

Clamping system:

-We adopt five fulctum hyperbolic elbow clamping mechnical which can tansfer power effectively and ensure the prcess of high speed response

-Low pressure mold protection system

-Tie bar adopts surface hard chromium plating processing

-Mould platen bottom support use copper material which can protect steel belt

-Automatic centerial lubricarion system which is easy for after service

Injection system:

-Optimization design of the injection unit to provide higher accuracy,ensure the higher stability

-Injection parts adopt double guide tie bars which improve inject technology

-Injection,holding pressure closed-loop control and precision back pressure control

-Cylinder temperature time monitoring to ensure high quality molding requirements.

Electric system:

-The advanced injection plastic machine computer work stable and accurate

-Intelligent method of defects in the course of injection process parameters

-It can save more than one hundred program

-It is equipped with mechanical arm eletrical interface which can be used to match the special mechanical arms for the injection robot.

Hydraulic system:

-Dual proportion load induction oil circuit is used to get steady operation,energy consumption variable with load and energy saving

-The oil box volume is large and the cooling system is arranged properly, it can reduc the oil efficiently

-High function oil pump,liquid motor, seal element can snsure low noise and zero penetration.

-All adopt international well-know hydraulic components

Technical parameters:

BN-380S INJECTION PART

PARTE INYECCIÓN UNIT A B C Screw diameter

Diámetro del tornillo mm 65 70 75 Screw L/D ratio

Tasa L/D del tornillo L/D 22 20.3 18.8 Shot volume

Volumen de Inyección cm3 1177 1366 1568 Injection weight(PS)

Peso de la inyección g 1071 1243 1426 oz 37.8 43.8 50.3 Injection rate

Tasa de inyección cm3/ s 320.1 371.2 426.1 Injection pressure

Presión de inyección Mpa 208 180 156.8 Screw speed

Velocidad del tornillo rpm 150 CLAMPING PART

PARTE DE CIERRE Clamping force

Fuerza de cierre kN 3800 Opening stroke

Apertura mm 680 Space between tie bars

Espacio entre barras mm 730X670 Mould thickness

Espesor de molde mm 250~680 Ejector stroke

Carrera del expulsor mm 180 Ejector force

Fuerza del expulsor kN 62 OTHERS

Otros Oil pump pressure

Presión de la bomba de aceite Mpa 16 Oil pump motor power

Potencia del motor de la bomba de aceite kW 39.4 Heater power

Potencia del calefactor kW 23 Machine dimension

Dimensión de la máquina m 7.2×1.9×2.4 Oil tank capacity

Capacidad del tanque de aceite L 580 Machine Weight

Peso de la máquina t 15.5

Processing photos:

Welcome for your inquiry.

Product Categories : Servo Motor Injection Molding Machine